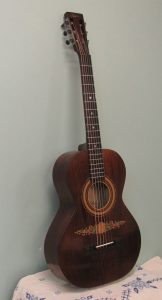

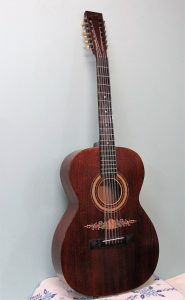

Decalomania 6 and 12

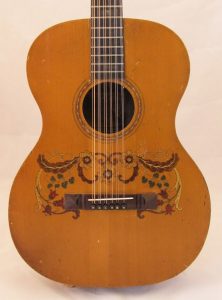

In the early 1900’s decorative decals were often used to add a little pizzazz to household objects. The guitar industry embraced the decal as a way to dress up very plain instruments. I don’t think that any company did this to greater effect than Oscar Schmidt, who used decals to imitate fancy rosettes and backstrips, and to add a touch of class, whether it was with ivy, musical instruments or beautiful ladies. I’ve had quite a few of these instruments over the years, and I’ve repaired a number of them as well. As they were intended to be budget models the quality can be pretty marginal, but some of them can be quite good for playing country blues or old time music. For me there has always been a charm that lay behind the decals, in the woods and the ways they were put together. I’ve thought for some time about making some copies of these instruments but a few obstacles stood in the way. Recently a confluence of events caused me to act and make a few. I couldn’t be more pleased with the results.

Recently I was at a friend’s place getting some wood. An older and very well respected classical guitar builder was there as well, picking up some sets of Brazilian rosewood. My friend introduced me to the builder, we started talking guitars and we were getting along pretty well. As we were discussing the finer points of resins used in varnish my friend said, “Todd’s the guy who uses white oak for back and sides.” “Oh” replied the older gentleman, as I could visibly see his estimation of me dropping in his mind. “And he’s the guy who ladder braces.” Now I was getting the full stink eye and the fellow slowly started backing away. He left without a handshake, without a polite goodbye. Nothing. That’s OK. I have thick skin.

A young man who was enrolled at a guitar building school came by my shop for a tour. We were talking about top bracing patterns and he said, “My teacher says that X bracing is structurally superior to ladder bracing.” I told him that his teacher was right, from an engineering standpoint, X bracing makes more sense and is superior, But what about the sound? Is the sound a consideration? The argument could be made that solid state is electronically superior to tube technology, but you can’t deny that a tube amp sounds better in certain applications.

I operate in the world of acoustic guitars, a world which is capable of taking itself a bit too seriously at times, losing sight of the big picture. I appreciate nice wood, I use it a lot of nice woods. I don’t believe in magic wood. I appreciate impeccable craftsmanship, I’m capable of some fairly fine work, I believe that most of the time, craftsmanship trumps wood. What it really boils down to for me is chasing a sound. Not necessarily the sound of concert halls and conservatories. Much of the time its a sound that was put down on record with great frequency in the 1920’s and 30’s, by some poor guy or gal who may have been a blind street musician, a barber, a sharecropper, a mill worker, a coal miner or a housewife who played at night and on weekends to pass the time. They played what they could afford, which usually wasn’t much, and they played the hell out of it. The decal guitars sum it all up beautifully, built quickly from lightweight materials, with a time saving, eye catching detail that allowed them to be some of the first mass produced budget guitars.

Oftentimes when people describe these guitars they say that the wood is birch. I had an epiphany at a certain point, working on a decal Stella 12 string, that the back and sides were actually poplar, which was used fairly extensively for necks in the early 1900’s. This isn’t to say that some of these guitars aren’t birch, certainly many were, but many were also poplar. Poplar’s green hues tend to vanish over time and it ends up looking a lot like birch. It is lighter in weight than birch and doesn’t have the pores, which makes it easier to finish. It takes stain beautifully and doesn’t require any pore filling. It’s light color allows it to be stained, painted, or covered with a tinted varnish to give it the look of woods like mahogany. All of these things were considerations for the guitar factories, whether it was the economy of the material, or in the time it took to finish it.

Poplar is a very misunderstood, humble wood. When some people think of poplar, they think of aspen, basswood or cottonwood, but the poplar used for guitars was none of these. It comes from the tulip poplar, Liriodendron Tulipifera, and is known as yellow poplar, sometimes magnolia (if they’re trying to put a shine on it). The trees grow fast and straight. It is a plentiful and inexpensive wood. It is nice to work, light in weight, fairly strong and very stable. It is greenish gray in color, not very attractive, never sexy. It’s often frowned on by woodworkers, not so much because of its workablility, mostly because of its appearance. It’s used in residential constructions as paint grade trim. In cabinet making it’s considered a secondary wood, again because of it’s appearance. it’s used for the interior part of a drawer, where stability is important, never for the face. As a lifelong woodworker, it took me a while to overcome my prejudice and come to terms with the fact that poplar was actually used for necks, bodies, braces, really every part of the guitar. The old “fruitwood” or “pearwood” fingerboard, most likely it’s poplar, “ebonized” with acid which causes it to turn black and deteriorate over time.

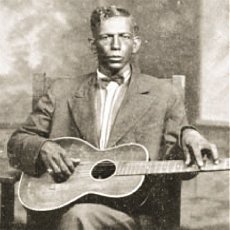

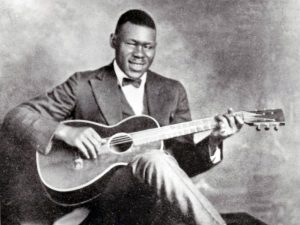

When we think of Leadbelly, we think of his iconic 12 string. Before he had that guitar, he had a big Stella, probably poplar, which he played while he was in prison. That’s the guitar he played on his Library of Congress field recordings. It was beat up and covered with stickers. It sounded great, but John Lomax, who would bring Leadbelly around to wealthy patrons to raise money, hated the guitar because it looked shabby. After searching for months Lomax finally found Leadbelly’s fancy 12 string, at a New Jersey furniture store. The poplar one probably got thrown in the trash. Willie McTell is pictured with a big decal Stella 12 in one of his earliest portraits. I’m fairly certain that guitar was poplar. Blind Blake’s guitar, while it doesn’t have a decal, may be a poplar Stella (judging from the dark finish and lack of ornamentation).

The combinations of all these things, snooty luthiers, old photos, old guitars, old sounds, facts etc. have made me want to build an all poplar decal guitar for quite some time. After a summer of building some very fancy, ornate instruments, I was ready for a palate cleanser. First I had to overcome some obstacles. Because you can’t readily order poplar guitar sets, that meant I had to saw the wood myself. That’s not a big deal, I’m used to sawing my own wood for guitars.

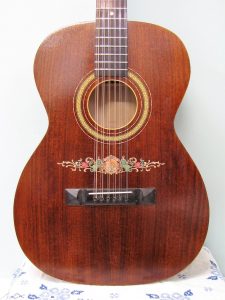

The biggest hurdle was the artwork for the decals. Also I wanted a stamp made in order to press my name into the headstock. My friend Gary Powell hit it out of the park in the art department. Gary scanned some decals from an old Stella guitar and mandolin. He vectorized the original artwork and reimagined the colors, seeing behind the dark varnish and patina, and bringing back some of the colors which had faded over the years. He added a special touch to the original decal design by replacing one of the women’s heads with that of my grandmother, using a portrait of her drawn by R.Crumb. We also used the Crumb Fraulini script to make a stamp for the headstocks. After the logo stamp is pressed into the wood of the headstock, I carefully painted it with gold metallic paint. Gary did an incredible job in record time. I would’ve been sunk without him. I joked with him that this was going to be called the “Gary Powell Model” as he’s also one of the best all around musicians I know.

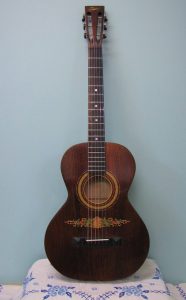

My approach for this round of guitars was to try to stay close to originals. I wanted to use poplar for all the parts of the instrument, build them with the same bracing patterns, use hide glue and finish them with varnish. I didn’t want to fuss over them. I wanted to build them relatively quickly, not carelessly, and not dwell on the finish. The guitars came together fairly smoothly. I had some downtime getting the decals printed, and there is a bit of a learning curve to applying them, especially the rosette decal, which is going on over a rather large hole in the top. I’m very happy with the way that they turned out. They are a little louder than the old ones, with a more dynamic sound, I likely take a little more away from the braces than the old guys. While I made them quickly for me, I don’t think it compares to how fast the old ones were built. The frets are modern, medium sized, more comfortable and more forgiving than what was used on the old guitars. The saddle is compensated so it plays in tune better than the old ones, and it is made of bone, rather than fret material or celluloid, They are extremely light in weight (one of the six strings is only 2 lbs 12 oz! the 12 is 4lbs 2 oz.). They have lots of volume and a very distinct old time tone.

One of my goals with these guitars was to have something to offer which was more affordable than my custom instruments.. They are well made, no frills instruments which have an old soul. They are perfect for people who play old style blues or hillbilly music who are looking for that sound, but don’t want to deal with the maintenance of an old guitar. If you are interested in one of them, contact me at todd@fraulini.com.

A very special thanks to my friend John Battaglia who provided me with the original decal Stella which I used as a reference for the art work. John was also instrumental in connecting me with the company that made the logo stamp. Also to Neil Harpe, who gave me a good primer on the process of printing decals. Finally, here’s Leadbelly, playing the guitar he had when John and Alan Lomax found him, which he used on his Library of Congress recordings, and a couple clips of myself playing the new ones:

18 Comments

Love the background and vision for these instruments. Very nice work!

thank you. I enjoyed the project.

Bless you

right on Brother. I am entirely blessed to be able to do this. This whole project reminded me of Don Young, who did it better than anyone.

Love the 12 string. Bet it sounds superb-

It sounds great for what it’s for….if that makes sense.

You are the coolest guitar builder on the planet. Hands down. What a great, great set of ideas! I'm so happy you carried them out.

Thanks Craig. I wish you were here to check them out and bang out some Leadbelly on the 12.

What a great project! And thanks for the blog……

I love the 12 string that you built for me more and more everyday!

You're the best, Todd. 8 years with a Fraulini you built and it gets better every day.

How many Fraulini's have you built to date?

Thank you. I forgot to number some, some I double numbered. It’s somewhere around 200 at this point, plus or minus 5.

What a great project! super inspiring! and great playing as well!!

Thank you Zohar. I hope all is well with you.

Great job, Todd! I'd like to find out more about Patton's Stromberg. I found one on Craigslist for $25, filled with mouse crap. After some cleaning and repairs, it sounds pretty good. Definitely a poplar model. Thanks!

Chuck Bickford

Hi Chuck,

The type of Stromberg that Patton is photographed with is a pretty ubiquitous. Sometimes they have basswood necks, which are no good and which people often confuse with poplar. They also tend to have tiny brass frets that are difficult to dress, especially if the neck is warped. Patton sure made it sound good, but they haven’t stood the test of time.

Hi Todd,

I’m not a musician, although I appreciate the old blues players. But I am a signpainter, and I have been doing some water-slide decals for piano and old beer signs. Yours are very cool and seem quite in keeping with the originals. Have you found a supplier of decal paper?

Hopeful, Lee Littlewood

Hi Lee,

Thanks for the feedback. A sign painter, Gary Powell actually helped me to put the decals together. They are based off of an old decal used on Stella guitars in the 1920’s, but I substituted the head of my grandmother for one of the ladies. Gary did a great job working with the old decal graphics. I am not printing these myself as it requires a high quality printer, which I lack. There are quite a few folks who print decals, but decal paper also seems to be fairly prevalent. I know that it comes in different thicknesses and I am using the thinnest so that the edges will disappear with a few coats of varnish. Thin also means its hard to work with, especially over the soundhole, and due to the large size of the decals.