Making a Case for Making a Case- Revisited

The Black Hole

May 18, 2018

Nick Lucas’ Galiano

June 15, 2020

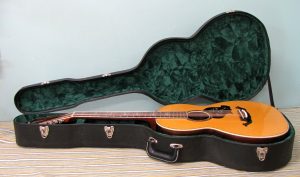

Guitar cases are an essential commodity for a guitar builder. Standard size cases can be purchased fairly easily, for a reasonable price. If you make and instrument that doesn’t fit into a standard case, your options are to have a custom case made, or to retrofit an over sized case. I have a few models that don’t fit into standard cases and require custom cases. I’ve had custom cases made by a variety of manufacturers and for one reason or another have not been satisfied, either with the case or with the service. I’ve retrofitted some over sized cases but was not happy with the results. One thing led to another and I eventually decided to try my hand at making my own cases. I made my first case two years ago and have made a few batches since as needed. Recently I revisited the process and made a few changes. I’m very happy with the result.

There’s a lot that goes into a guitar case and the process is almost as involved as making a guitar. There are a variety of materials used, wood, fabric, hardware and adhesives, and narrowing down the many choices is an ongoing process. My goal has been to make a case that had the look of the classic old prewar cases, streamlined and protective, but still lightweight. My intention was not to make a flight case, just something that did it’s job and looked good.

I had not been entirely happy with the way that I had been laminating my sides, so my first step was to revisit my molds and my clamping approach. I’m an old school guy with a cramped shop. I opted to use the tools I had on hand rather than invest in a vacuum clamping system, I don’t have the space and could use the money for more pressing matters. With the help of my buddy Chris Jungbluth, I came up with a system using C-clamps and quick grip clamps. It was very effective and fast.

The next thing I wanted to change was the interior material. I had been going to the local fabric store and the most appropriate thing that they had was flannel. Flannel was used on some old cases in the early 20th century. It certainly looks great but it’s difficult stuff to work with. You need to iron it and it shows off every imperfection in your work. I had wanted to switch to velvet but had been unable to find a source for affordable quality material. Recently I found such reliable source and made the switch. The velvet comes in variety of vibrant colors, it’s more heavy duty than flannel, it does not need to be ironed, which is a huge time saver, and it is much more forgiving than flannel.

I also made a few changes on hardware. I went for a slightly more modern cinch type latch, rather than the more old school flip latch. I felt that this type of latch was more secure, and it actually pulls the lid tightly to the bottom. Sometimes the flip latches require you to do a little finagling in order for the case to close properly. Using a smaller sized, nickel plated latch, it still has an old school look, but adds a little more security.

I made four cases during this round, and there’s nothing quite like repetition to help get a process down. The final case, my piece de resistance, had a gator exterior and red velvet interior. It had a super rich, decadent look that existed in some of the classic cases of yesteryear but which has vanished from modern cases.

I was very pleased with the way that this batch turned out. I feel that I’ve got the process down to a point that makes sense for me to continue. I’ve eliminated the bottleneck that some of the case companies were creating for me, and I’m much happier with the end product. I’m not looking to make cases for all of my models, nor am I looking to make them for anyone else, but I’m happy to add these cases to mix.

7 Comments

Looks great! I am making Gibson L0 – L1 style guitars and think I may have to make cases also. Are there any resources that may help me. What is your fabric source for lining. Thanks for any help. William

Thank you. I’d recommend Steve Kirtley’s site http://www.stevekirtley.org/vintagecases.htm . Steve also has a vintage case Facebook group which is helpful. If you email me, I can answer some questions that you may have along the way.

Thank you for the reply. I am aware of these sites by am working out a mold for arching top of case. Thanks William. Hope to stay in touch if it’s ok.

Awesome cases. Do the baritone 12 string models get your hand made cases? Your’e making it hard not to own both a bajo sexto and a Stella tupe baritone!

The Angelina comes with a custom case, mainly because it requires one. The Francesca fits in a stock case, so at the moment, it does not come with a custom case.

I’m in the process of making a case for my guitar, it doesn’t fit properly in any off-the-shelf cases and the manufacturer discontinued the case with the model. I am very concerned about the liner material damaging the finish on my guitar, are you willing to share your source for liner material (or sell me enough to use in my case?)

I used to get flannel at a local JoAnn Fabric. Flannel is a little difficult to work with, but it does the trick. I’d recommend going to a local fabric store and seeing fabric in person, picking out what you like. If you know you want to use a certain fabric, velvet, crushed velvet etc. there are several sources available online. You can also check ebay or etsy for “velvet fabric” or “crushed velvet fabric” That way you can get exactly what you want in terms of texture and color. Good luck.